Powder Coating vs Traditional Paint

For this blog, we will explain the benefits of powder coating, compare them to traditional paint, and let you decide which one is the superior choice.

Understanding the Science behind Powder Coating

Powder Coating gives consumers, businesses, and industries one of the most economical, longest-lasting, eco-friendly, and most color-durable quality finishes available on virtually any type of metal. The methods of applying it allow for a wide range of personalization, such as matte finishes of finishes with quite a bit of shine, it really all depends on the experience of who is doing the job.

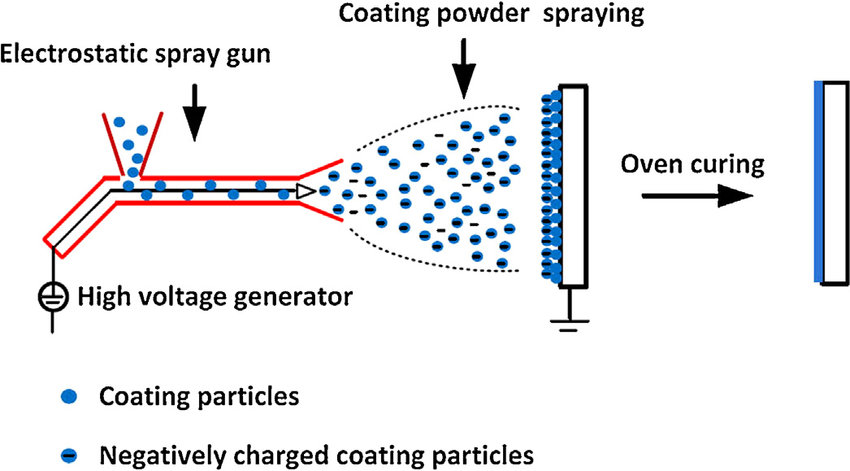

There are two main methods of powder coating—electrostatic spray deposition (ESD) and fluidized bed application. Either process can produce an even, hard finish which is generally more durable, cost-effective, and environmentally-friendly than a comparable liquid coating.

But how does it work? well, Powder coating is a solventless system; it does not depend on the use of a solvent. It uses the performance constituents of solid TP or TS materials. It can be a homogeneous blend of the plastic with fillers and additives in the form of dry, fine particles of a compound similar to flour. This basically means that powder coating doesn’t pollute air nor water.

heres a video that pretty much sums it up

Electrostatic powder coating

Electrostatic powder coating began in the early 1960s with the coating of pipes for increased durability and for insulating electrical components. In the 1960s electrostatic coating had already been used in many industries for finishing purposes with paints containing solvents.

With the introduction of powder coatings, there was no need for solvents, therefore there are no volatile organic compounds evaporating into the atmosphere or the health risk of inhaling them. Another environmental and economical advantage of powder coating is that the overspray can be collected and recycled back into the coating process. For this reason, the material efficiency of powder coatings can come close to 100%. There has been a fast growth of the powder coating industry in the last couple of decades due to increased productivity and efficiency from switching from conventional solvent paints.

Compared to traditional liquid coatings, powder coatings are more durable, impact resistance, corrosion resistance, and chemical resistant. Powder coatings fade less than liquid coatings and can be tailored for many different applications by changing color, gloss, coating thickness, and texture. [2] There are four main steps in the powder coating process: charging, transport, adhesion/deposition, and finally curing.

The basic principle behind powder coating is a charged particle, usually, a polymer is accelerated toward a grounded workpiece and is adhered to the workpiece by means of attraction. The coated workpiece is then cured at an elevated temperature transforming the powder coating into a smooth, and uniform polymer film.

Fluidized Bed Application

A fluidized bed is an open box with a “plenum” chamber underneath, separated by a porous membrane. Air is introduced into the lower chamber, which then passes into the upper box uniformly. The density of free-flowing powder in the upper box is reduced by the air, such that 24-inch deep powder in a “dead” bed rises to 28 or 30 inches deep.

In a properly moving fluid bed, you can reach your hand all the way down the bottom of the box. Depending on the powder in the bed, there may be a substantial amount of dusting coming out of the box. Powders designed for fluid bed applications generally have larger particle sizes than the “thin-film” electrostatic powders and are ideally spherical in shape to allow easy free flow properties.

Many people would say at this that powder coating simply is the better alternative, and yes in many cases it is. However, this all comes down to who is doing the job and his or her definition of quality work.

Quality in a service or product is not what you put into it, it is what the customer or client gets out of it.

Peter Drucker

So to end this blog post it’s wise to think to yourself: What do I need? What do I want? and Where will I get it done?

Here at Rockford Powder Coating, we believe in fair prices for great work, so if you ever want to powder coat anything Check Out Our Services